This engagement focused on stabilizing plant performance and restoring financial health by addressing scheduling breakdowns, unclear accountability, and operational inefficiencies. Through disciplined execution and leadership alignment, the organization reversed negative EBITDA and established a foundation for sustained improvement.

Reduction in Downtime

Increased Output Through Reduced Sanitization Downtime

Increased Output Through Pre-batching Process

An innovative food solutions manufacturer faced operational setbacks at one of its key facilities that resulted in negative EBITDA performance. Lost production time, unclear roles across plant teams, and inconsistent scheduling created confusion and limited accountability on the plant floor.

These issues led to sub-optimal execution, frequent disruptions, and continued financial underperformance. Leadership engaged Adonis Partners to stabilize operations, clarify responsibilities, and restore plant-level performance.

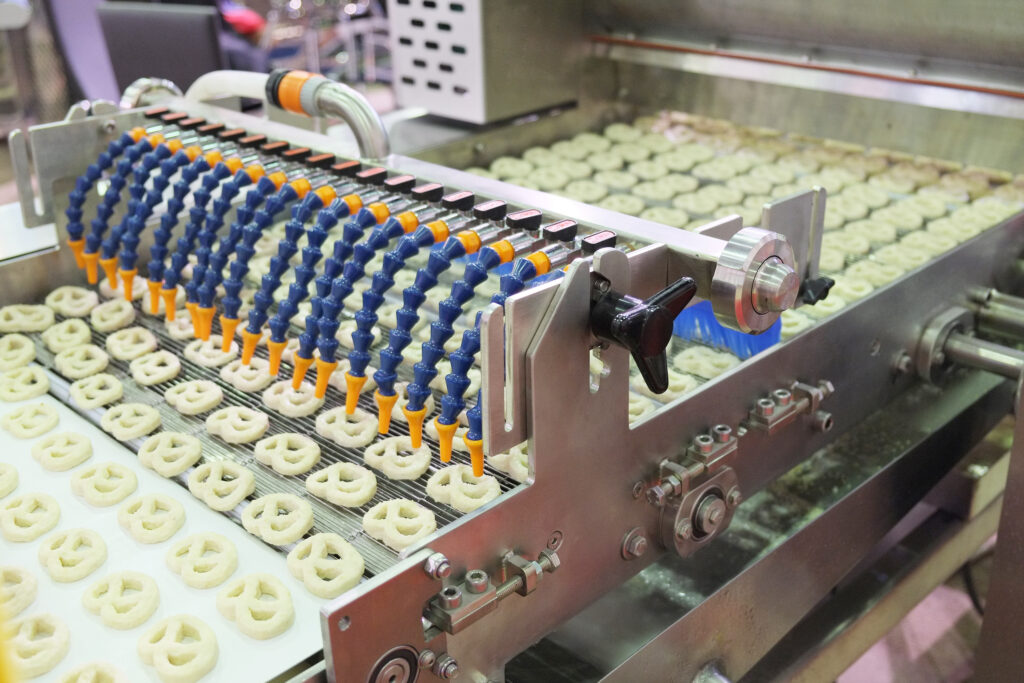

Adonis Partners worked directly with the client’s scheduling team to standardize planning and execution. An optimized Production Wheel was developed to bring structure and consistency to scheduling decisions.

Additional initiatives focused on preparing the plant for higher-margin production. These included grouping similar allergen recipes to reduce changeover complexity and configuring production setups to prioritize high-margin lines. To strengthen communication and accountability, Adonis introduced regular plant operational meetings with standardized agendas and developed clear Roles, Responsibilities, and Expectations for key plant leaders.

Together, these actions improved coordination, reduced variability, and reinforced a culture of ownership across the operation.

Each initiative delivered meaningful financial and operational results. Annualized savings of $450k to $600k were achieved through reduced sanitation downtime enabled by improved scheduling and optimized production setup. Streamlining the pre-batching process generated an additional $250k in savings, while improved inventory management reduced the frequency of disruptive scheduling changes.

These gains stabilized plant performance, reversed negative EBITDA, and positioned the operation to support sustained profitability and long-term growth.

We help leadership teams identify where performance is constrained and what it takes to unlock results. Share a few details and we’ll explore whether a similar approach makes sense for your organization.

Food & Beverage Manufacturer

Scale: $34.4M Annual Revenue

✓ Devised an optimized Production Wheel

✓ Boosted output by $450k-$600k through reduced sanitation downtime

✓ Reduced schedule changes by improving raw material supply